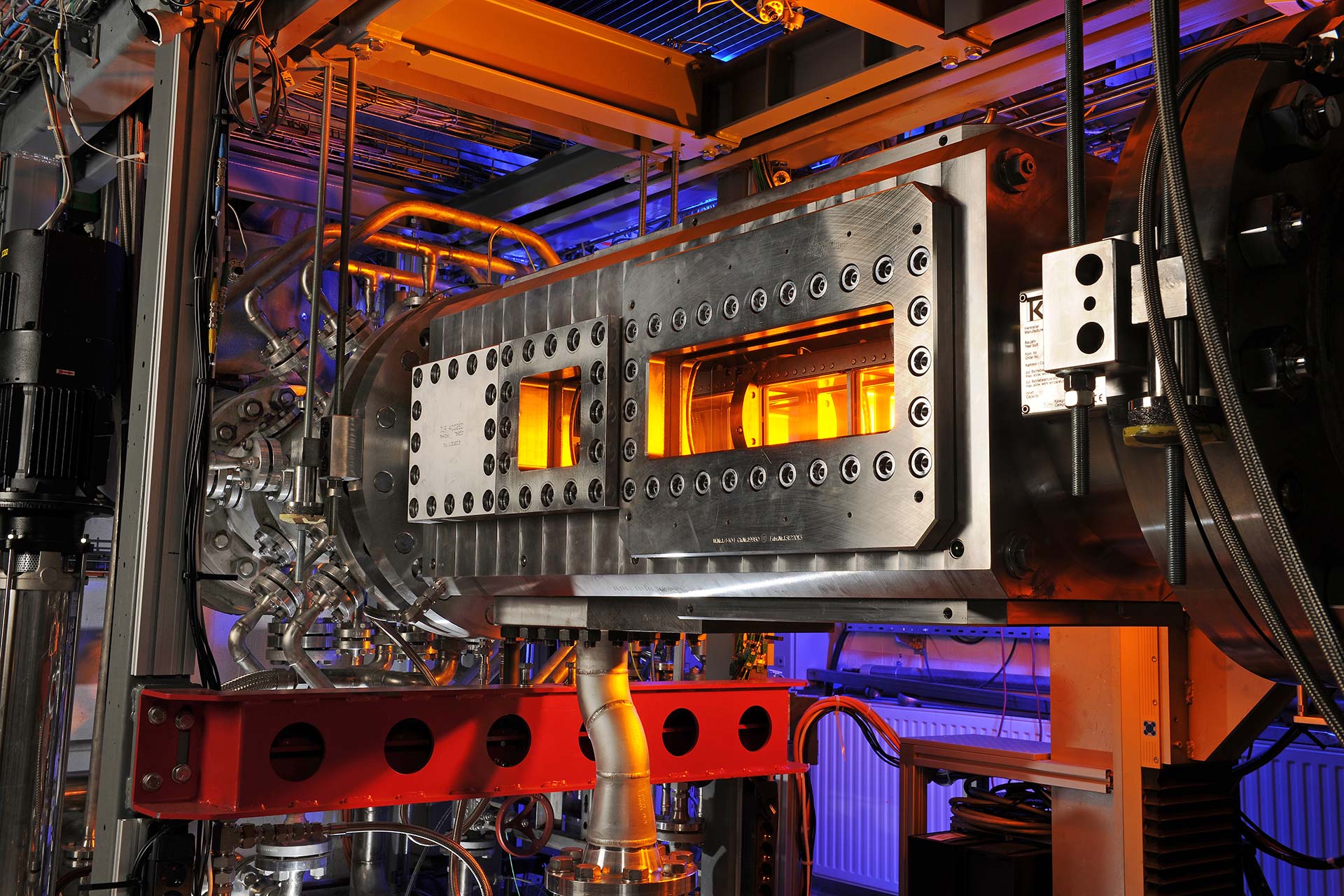

The numerical simulations during the sequential combustion system development will be crucially complemented by dedicated tests of a simplified sequential combustor geometry at GT relevant operating conditions in an optically accessible rig, providing experimental data for both numerical modelling validation and optimisation of the engine operation concept.

Full-scale single-can combustor prototypes will be manufactured and tested both at atmospheric conditions for validation of ignition procedures and at full engine operating conditions (including temperature, pressure, fuel and air mass-flows) to ultimately validate the combustor operation at all natural gas-hydrogen blends, up to 100% H2, thus successfully achieving TRL6.